You're allready out of fuel, High egt's are usually a sign of too lean of a mix in the combustion chamber, adding the secondary turbo will only increase your egt's. You need to check your pump for maintained pressure at the higher rpm's, Ill bet the fuel pressure is dropping off to the injectors, you probably would do better to have your injector pump checked, of it checks good, with the mods you listed mostlikely a high volume pump would be the next change and re tune.

99 2500 4wd

stage 3 injectors and edge attitude programmer

many other mods

Reply

Reply

The power of the diesel is directly related to the fuel input. As you know, we heat the air, forcing it to expand, resulting pressure moves the piston.

The power of the diesel is directly related to the fuel input. As you know, we heat the air, forcing it to expand, resulting pressure moves the piston.

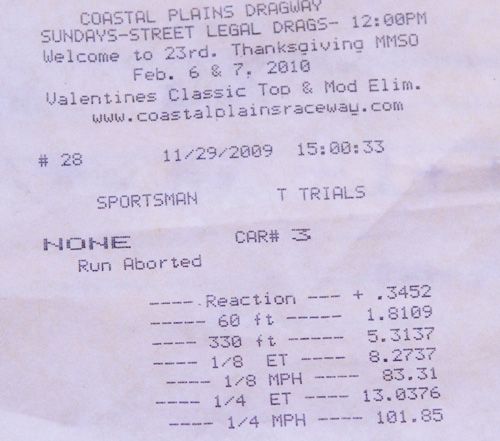

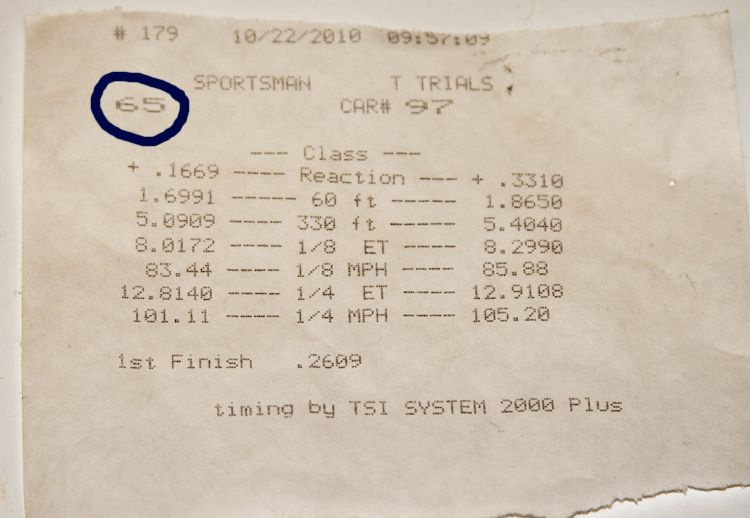

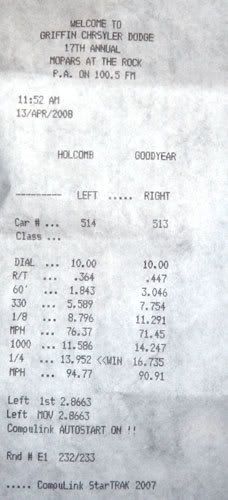

My truck is by no means fast as compared to MANY of the newer Dodge CTDs. It does alright for a 1st generation CTD though.

My truck is by no means fast as compared to MANY of the newer Dodge CTDs. It does alright for a 1st generation CTD though.