I would put it almost to the furthest end of the piping run. Also, control the bypass to pressure not Delta T. If your running from a chiller, it will take care of the temperature for you.

Hi expert forumer,

I'm beginner in control automation. I'm need some advice from all of you regarding to this

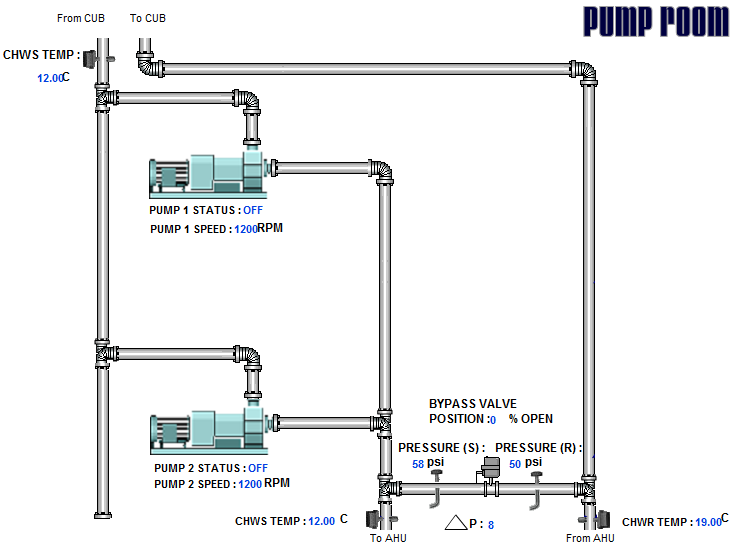

1) which is best location to place water pressure sensor to control Variable Speed Drive Pump? - refer picture below

2) Which parameter (delta pressure or delta Temperature) to control bypass valve?

Please refer to this picture for more info.

Thank you

I would put it almost to the furthest end of the piping run. Also, control the bypass to pressure not Delta T. If your running from a chiller, it will take care of the temperature for you.

"It's not that I'm smart, it's that I stay with the problem longer

Albert Einstein

This tends to be argued but I'd basically agree w/Xarralu. 2/3 or further from the pump so you get more of a system pressure and can sense the further zones better. Sensing your 'furthest' zone helps ensure you have proper pressure out to those zones. Granted one many times can tune due to poor locations, but it's better just to have it right from the start, especially since sometimes it takes a whole lot of time to tune...

"How it can be considered "Open" is beyond me. Calling it "voyeur-ed" would be more accurate." pka LeroyMac, SkyIsBlue, fka Freddy-B, Mongo, IndyBlue

BIG Government = More Dependents

"Any 'standard' would be great if it didn't get bastardised by corporate self interest." MatrixTransform

My 5 yr old son "Dad, Siri is not very smart when there's no internet."

"How it can be considered "Open" is beyond me. Calling it "voyeur-ed" would be more accurate." pka LeroyMac, SkyIsBlue, fka Freddy-B, Mongo, IndyBlue

BIG Government = More Dependents

"Any 'standard' would be great if it didn't get bastardised by corporate self interest." MatrixTransform

My 5 yr old son "Dad, Siri is not very smart when there's no internet."

The differential pressure should be at the most remote AHU. Find out the minimum required Diff pressure for the coil of this AHU and that should be your setpoint. This setpoint should be maintained by modulating the pump speed. If you maintain this pressure then all AHU's will have sufficient water flow

The Bypass control is a different story. Your system consists in essence of a primary and a secondary loop but without the use of primary and secondary pumps. I am seeing this setup more and more and this will probably be the future for chilled water control.

The reason for the Bypass is to ensure minimum flow through the chillers. To make this work you will need differential pressure sensors for each chiller or flow meters for each chiller.

When the load in the building decreases, the AHU chilled water valves will close and pump speed will decrease. Until you get to the point that there is not enough water flow through the chiller. At this point you will start to modulate the bypass valve open. Because the bypass begins to open, the diff pressure at your most remote AHU will drop causing the pump speed to increase. And system will find a new balance point at which Pump Speed maintains the most remote AHU Diff Pressure at setpoint and the Bypass Valve is opened to the point that the chillers have there minimum required flow.

By the way in your picture, I believe your Chilled water labeling "To AHU" and "From AHU" and your 2 pressure sensors are reversed

Last edited by exwtk; 01-22-2012 at 12:16 AM.

Actually ... your labeling might be correct but then the discharge and suction of the pump is backwards. Typically with centrifugal pump the water line in line with the pump shaft is the suction and the one coming out of the pump housing is the discharge.

Most Sensors should be put 10 Pipe Diameters from the closest fitting, as a general rule of thumb too. Flow, Pressure... anything that can be affected by turbulence.

Thank you Exwtk, I understand it the function to control it.

You need a flow meter. http://www.trane.com/commercial/libr...31_4/index.asp

.

"The bitterness of poor quality remains long after the sweetness of low price is forgotten". --Benjamin Franklin

"Don't argue with an idiot, they will drag you down to their level and beat you with experience". --Mark Twain

http://www.campbellmechanical.com

While I understand this concept, have been on a site where I have seen a pressure sensor installed at the ground floor, while the pumps are in the PH level (42 floors up). I couldn't get the differential pressure to vary between the supply and return. Both supply and return pressure sensors are at the Ground Floor, and the differential pressure is essentially 0 KPa. Could you clarify where the supply and return pressure sensors should be installed?

Assuming 5 PSI for each floor, that's 210 PSI head pressure to the ground floor. Both the Supply and Return read 210 PSI roughly, meaning 0 differential pressure, resulting in the VFD Pumps running at max speed.

>Both supply and return pressure sensors are at the Ground Floor, and the differential pressure is essentially 0 KPa. Could you clarify where the supply and return pressure sensors should be installed?

I would bet the static head pressure far exceeded your pressure sensor's max pressure rating and that's why it read 0. 210psi is a lot for a dP sensor to handle.

Propagating the formula. http://www.noagendashow.com/

Just an FYI but Veris has a DP Sensor that is rated to 250PSI if you need one. http://www.veris.com/docs/Datasheets/PW2_d01121.pdf

If you can't fix it with JB Weld, Duct Tape, and Ty Wire it has to be replaced.

No good deed goes unpunished.

If you want to take off friday to go fishing then make sure you train your helper right.